SD755L5-RH

SD755L5-RH

|

|

||||||

MG00004

MG00004

|

|

||||||

MD00420

MD00420

|

|

||||||

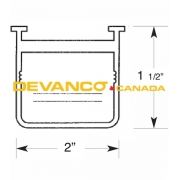

P220-2K

P220-2K

|

|

||||||

DS75-SEAL

DS75-SEAL

|

|

||||||

MG020-B-2E-04

MG020-B-2E-04

|

|

||||||

ODCC-SPEC.ORDER

ODCC-SPEC.ORDER

|

|

||||||

LDCO800

LDCO800

|

|

||||||

PG-K-R50

PG-K-R50

|

|

||||||

CP-ARM-NEW

CP-ARM-NEW

|

|

||||||

ME123-M-BLK-U

ME123-M-BLK-U

|

|

||||||

1224-2-WHITE

1224-2-WHITE

|

|

||||||

MX00140-NEW

MX00140-NEW

|

|

||||||

.393-6-L

.393-6-L

|

|

||||||

25-60502

25-60502

|

|

||||||

108D34

108D34

|

|

||||||

OSH-6114-CONT-R

OSH-6114-CONT-R

|

|

||||||

3BLM-BC

3BLM-BC

|

|

||||||

K-T5011L4

K-T5011L4

|

|

||||||

HSCFV112

HSCFV112

|

|

||||||

MK00642

MK00642

|

|

||||||

FGS-634

FGS-634

|

|

||||||

H12G09-SS

H12G09-SS

|

|

||||||

H12G03-SS

H12G03-SS

|

|

||||||

17JW

17JW

|

|

||||||

.306-2-5/8-RH-C

.306-2-5/8-RH-C

|

|

||||||

OPH-6113-CONT-R

OPH-6113-CONT-R

|

|

||||||

MX00147-OLD

MX00147-OLD

|

|

||||||

SHAFT017

SHAFT017

|

|

||||||

CAP590

CAP590

|

|

||||||

36254R

36254R

|

|

||||||

GHX-6112-CONT-L

GHX-6112-CONT-L

|

|

||||||

OPH-6112-CONT-R

OPH-6112-CONT-R

|

|

||||||

MV-00297

MV-00297

|

|

||||||

MT22-BLACK-RH

MT22-BLACK-RH

|

|

||||||

RS1039-C

RS1039-C

|

|

||||||

75-10170

75-10170

|

|

||||||

TH827-24V

TH827-24V

|

|

||||||

NTE5326

NTE5326

|

|

||||||

PED4272

PED4272

|

|

||||||

1005-1-3/4-12

1005-1-3/4-12

|

|

||||||

Z9003-MAX

Z9003-MAX

|

|

||||||

41A7635

41A7635

|

|

||||||

41A7562

41A7562

|

|

||||||

7FT-RAIL-CHAIN

7FT-RAIL-CHAIN

|

|

||||||

355LMC

355LMC

|

|

||||||

CR2450

CR2450

|

|

||||||

41A6102

41A6102

|

|

||||||

13-10024

13-10024

|

|

||||||

17300

17300

|

|

||||||

OPH-6533-ECB

OPH-6533-ECB

|

|

||||||

TIMER031

TIMER031

|

|

||||||

BRAKE011

BRAKE011

|

|

||||||

RADIO-KIT004

RADIO-KIT004

|

|

||||||

298601

298601

|

|

||||||

MDTK

MDTK

|

|

||||||

HAR-11

HAR-11

|

|

||||||

218014-02

218014-02

|

|

||||||

RV-300

RV-300

|

|

||||||

3002-200FT

3002-200FT

|

|

||||||

200BL

200BL

|

|

||||||

1006-1-3/8-10'

1006-1-3/8-10'

|

|

||||||

32-48-110

32-48-110

|

|

||||||

RN1127

RN1127

|

|

||||||

BK312

BK312

|

|

||||||

25-10103

25-10103

|

|

||||||

LMHNTG

LMHNTG

|

|

||||||

50195

50195

|

|

||||||

GREASE

GREASE

|

|

||||||

25-10113**DISC

25-10113**DISC

|

|

||||||

28103

28103

|

|

||||||

MODKIT027B1

MODKIT027B1

|

|

||||||

19-48ML

19-48ML

|

|

||||||

R-831-P

R-831-P

|

|

||||||

17335

17335

|

|

||||||

29200

29200

|

|

||||||

CELLOPENER-365

CELLOPENER-365

|

|

||||||

PD1614B000

PD1614B000

|

|

||||||

2807.200.280

2807.200.280

|

|

||||||

50181

50181

|

|

||||||

461-0002-08

461-0002-08

|

|

||||||

D1101KH

D1101KH

|

|

||||||

HAE00087

HAE00087

|

|

||||||

LZR-H100

LZR-H100

|

|

||||||

R2T

R2T

|

|

||||||

GX-200

GX-200

|

|

||||||

K41-0157-000

K41-0157-000

|

|

||||||

XF208VAC12

XF208VAC12

|

|

||||||

41184R

41184R

|

|

||||||

DS75-INSULATED

DS75-INSULATED

|

|

||||||

PHOTO-073

PHOTO-073

|

|

||||||

CCTD-04

CCTD-04

|

|

||||||

40655R

40655R

|

|

||||||

FM145

FM145

|

|

||||||

18205

18205

|

|

||||||

SETR2641AM1AN-C

SETR2641AM1AN-C

|

|

||||||

DC1000-125

DC1000-125

|

|

||||||

110001-BULB-PER-FT

110001-BULB-PER-FT

|

|

||||||

10TD900INDHH4

10TD900INDHH4

|

|

||||||

7-6088

7-6088

|

|

||||||

Your Search

Your Search