ARMP5

ARMP5

|

|

||||||

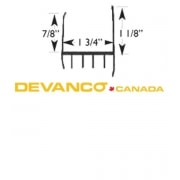

MDT-1A

MDT-1A

|

|

||||||

MK-01179

MK-01179

|

|

||||||

MD-00487

MD-00487

|

|

||||||

TRACK-1458-SS

TRACK-1458-SS

|

|

||||||

BOARD060R

BOARD060R

|

|

||||||

19-41119M

19-41119M

|

|

||||||

CF-101-12

CF-101-12

|

|

||||||

CRBH751L5-RH

CRBH751L5-RH

|

|

||||||

760130

760130

|

|

||||||

LITH-9V

LITH-9V

|

|

||||||

42413

42413

|

|

||||||

41C5141-1

41C5141-1

|

|

||||||

Q013

Q013

|

|

||||||

CHAIN031

CHAIN031

|

|

||||||

IRB-MON-RX

IRB-MON-RX

|

|

||||||

ALUM-506

ALUM-506

|

|

||||||

ULTRA-II-D-TEK

ULTRA-II-D-TEK

|

|

||||||

WOR

WOR

|

|

||||||

WASHER008

WASHER008

|

|

||||||

CONTACTOR041

CONTACTOR041

|

|

||||||

RA-AD-WWS-MULTI

RA-AD-WWS-MULTI

|

|

||||||

HSC-1000

HSC-1000

|

|

||||||

MK00701

MK00701

|

|

||||||

IS40P

IS40P

|

|

||||||

BK307

BK307

|

|

||||||

BOARD070ER

BOARD070ER

|

|

||||||

T751L5

T751L5

|

|

||||||

AK-21

AK-21

|

|

||||||

797

797

|

|

||||||

LA500DC

LA500DC

|

|

||||||

41AC075-2

41AC075-2

|

|

||||||

24851

24851

|

|

||||||

NTE5326

NTE5326

|

|

||||||

PEDALU42

PEDALU42

|

|

||||||

QUICK_CLOSE

QUICK_CLOSE

|

|

||||||

8010-3FT

8010-3FT

|

|

||||||

41A5021-9G-315

41A5021-9G-315

|

|

||||||

T-53-S

T-53-S

|

|

||||||

11801

11801

|

|

||||||

PL-A03-NEW-BRD

PL-A03-NEW-BRD

|

|

||||||

27-20301

27-20301

|

|

||||||

25-10578

25-10578

|

|

||||||

Z9403

Z9403

|

|

||||||

25-10402

25-10402

|

|

||||||

27-20202

27-20202

|

|

||||||

.243-2-R

.243-2-R

|

|

||||||

25-10113**DISC

25-10113**DISC

|

|

||||||

37028C.S

37028C.S

|

|

||||||

P294-K

P294-K

|

|

||||||

LDM-1

LDM-1

|

|

||||||

17335

17335

|

|

||||||

Z9961

Z9961

|

|

||||||

LZR-MICROSCAN1T

LZR-MICROSCAN1T

|

|

||||||

BEA-35-1555

BEA-35-1555

|

|

||||||

202-0019

202-0019

|

|

||||||

MSJ-6113-M-N1-RH

MSJ-6113-M-N1-RH

|

|

||||||

P-535T

P-535T

|

|

||||||

041-0365-000

041-0365-000

|

|

||||||

150BL

150BL

|

|

||||||

WASHER035

WASHER035

|

|

||||||

NIR-50-325-KIT

NIR-50-325-KIT

|

|

||||||

WR2

WR2

|

|

||||||

751-CDN

751-CDN

|

|

||||||

LA500CONTUL

LA500CONTUL

|

|

||||||

1184HD

1184HD

|

|

||||||

AHB-716

AHB-716

|

|

||||||

CDJH-34-115-CON-R

CDJH-34-115-CON-R

|

|

||||||

02-403N4-XALD

02-403N4-XALD

|

|

||||||

CGH503L5-RH

CGH503L5-RH

|

|

||||||

MOTOR255

MOTOR255

|

|

||||||

MF00003

MF00003

|

|

||||||

27-83190

27-83190

|

|

||||||

RBH105L5-LH

RBH105L5-LH

|

|

||||||

E/1929/235

E/1929/235

|

|

||||||

26124

26124

|

|

||||||

UTIL025

UTIL025

|

|

||||||

50690

50690

|

|

||||||

1004-2-12'

1004-2-12'

|

|

||||||

BG790-5021

BG790-5021

|

|

||||||

SM101

SM101

|

|

||||||

27222A

27222A

|

|

||||||

MS-00002

MS-00002

|

|

||||||

CAP2D

CAP2D

|

|

||||||

15480

15480

|

|

||||||

HINGE-211-PCG

HINGE-211-PCG

|

|

||||||

M3-2314-WHITE

M3-2314-WHITE

|

|

||||||

MIRF-Z2

MIRF-Z2

|

|

||||||

CABLE_364SS-250

CABLE_364SS-250

|

|

||||||

37355

37355

|

|

||||||

MK-00646

MK-00646

|

|

||||||

MOD060-14FT

MOD060-14FT

|

|

||||||

25-60100

25-60100

|

|

||||||

029C98205

029C98205

|

|

||||||

CF-101-10

CF-101-10

|

|

||||||

LIMIT-KIT-BCSI

LIMIT-KIT-BCSI

|

|

||||||

27191A

27191A

|

|

||||||

PRO-H-5011E-LH

PRO-H-5011E-LH

|

|

||||||

K74-18379

K74-18379

|

|

||||||

K32-10540

K32-10540

|

|

||||||

Your Search

Your Search