CG-HOIST-DBLE-114

CG-HOIST-DBLE-114

|

|

||||||

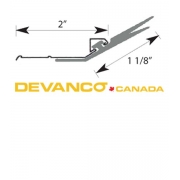

7-6088

7-6088

|

|

||||||

PHOTO-060

PHOTO-060

|

|

||||||

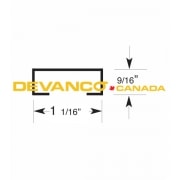

OPH-6112-M-N1-RH

OPH-6112-M-N1-RH

|

|

||||||

MTS1

MTS1

|

|

||||||

STD-YZ-MINI

STD-YZ-MINI

|

|

||||||

39902R

39902R

|

|

||||||

GH-353-1.5

GH-353-1.5

|

|

||||||

HAE00070

HAE00070

|

|

||||||

20FT-TROLLEY-SET

20FT-TROLLEY-SET

|

|

||||||

410-0003

410-0003

|

|

||||||

ETBHW-311-3/4HP

ETBHW-311-3/4HP

|

|

||||||

SL585501UL

SL585501UL

|

|

||||||

PUSH148

PUSH148

|

|

||||||

1004-134-8'

1004-134-8'

|

|

||||||

TRANSF112

TRANSF112

|

|

||||||

C9/90-KIT

C9/90-KIT

|

|

||||||

PPV3M

PPV3M

|

|

||||||

LJ8950W

LJ8950W

|

|

||||||

.273-2-L-C

.273-2-L-C

|

|

||||||

MP-00025

MP-00025

|

|

||||||

27222A

27222A

|

|

||||||

MK-00059

MK-00059

|

|

||||||

K001D8397-1

K001D8397-1

|

|

||||||

RBH103L5-LH

RBH103L5-LH

|

|

||||||

8010-8FT

8010-8FT

|

|

||||||

FMB01DW24

FMB01DW24

|

|

||||||

41B0873

41B0873

|

|

||||||

029C98205

029C98205

|

|

||||||

CRBH751L5-LH

CRBH751L5-LH

|

|

||||||

10-1036-4

10-1036-4

|

|

||||||

27191A

27191A

|

|

||||||

MK-00605

MK-00605

|

|

||||||

MG020-B-2E-04

MG020-B-2E-04

|

|

||||||

720118

720118

|

|

||||||

PRO-LH-5011R-RH

PRO-LH-5011R-RH

|

|

||||||

TRACKS-SET-3

TRACKS-SET-3

|

|

||||||

RBH101L5-RH

RBH101L5-RH

|

|

||||||

SLC-221

SLC-221

|

|

||||||

7001-18-CHARCOL

7001-18-CHARCOL

|

|

||||||

L-4-18-0-M

L-4-18-0-M

|

|

||||||

PS243F

PS243F

|

|

||||||

LM21XP

LM21XP

|

|

||||||

JRGX114

JRGX114

|

|

||||||

1224-2-WHITE

1224-2-WHITE

|

|

||||||

.437-6-L

.437-6-L

|

|

||||||

PRO-APTB-5011-R

PRO-APTB-5011-R

|

|

||||||

.393-6-L

.393-6-L

|

|

||||||

15-19478

15-19478

|

|

||||||

MK-00005

MK-00005

|

|

||||||

K20-1050B-2LP

K20-1050B-2LP

|

|

||||||

029-98090

029-98090

|

|

||||||

LD7LP

LD7LP

|

|

||||||

MA116

MA116

|

|

||||||

PEDALU42-HOOD

PEDALU42-HOOD

|

|

||||||

FGS-634

FGS-634

|

|

||||||

27-48-100

27-48-100

|

|

||||||

ME120-PC

ME120-PC

|

|

||||||

K72-12487

K72-12487

|

|

||||||

41A7276

41A7276

|

|

||||||

VBELT_5L345

VBELT_5L345

|

|

||||||

TR490

TR490

|

|

||||||

TH827-24V

TH827-24V

|

|

||||||

1010-PER-FOOT

1010-PER-FOOT

|

|

||||||

DD-KIT

DD-KIT

|

|

||||||

1005-1-3/4-12

1005-1-3/4-12

|

|

||||||

STAR450-315

STAR450-315

|

|

||||||

8FT-RAIL-CHAIN

8FT-RAIL-CHAIN

|

|

||||||

41DJ002

41DJ002

|

|

||||||

T-931-M

T-931-M

|

|

||||||

.468_5-1/4"-RH

.468_5-1/4"-RH

|

|

||||||

SEA433

SEA433

|

|

||||||

RADIO-KIT004

RADIO-KIT004

|

|

||||||

HAE00001

HAE00001

|

|

||||||

4004-8FT

4004-8FT

|

|

||||||

1003-4"-200FT

1003-4"-200FT

|

|

||||||

1003-1-5/8-12'

1003-1-5/8-12'

|

|

||||||

1104-18FT-CREAM

1104-18FT-CREAM

|

|

||||||

93-00240

93-00240

|

|

||||||

H11G01

H11G01

|

|

||||||

EP2987

EP2987

|

|

||||||

R5201

R5201

|

|

||||||

BK312

BK312

|

|

||||||

25-10101

25-10101

|

|

||||||

25-10100

25-10100

|

|

||||||

HBS23LU

HBS23LU

|

|

||||||

41A5034

41A5034

|

|

||||||

19-48ML

19-48ML

|

|

||||||

V3564-00-W-200

V3564-00-W-200

|

|

||||||

MTR1

MTR1

|

|

||||||

H14G03

H14G03

|

|

||||||

50181

50181

|

|

||||||

PB-001

PB-001

|

|

||||||

1184HD.1

1184HD.1

|

|

||||||

15-50B72QGH

15-50B72QGH

|

|

||||||

RENO-BX4

RENO-BX4

|

|

||||||

OTBH-6113-AM05

OTBH-6113-AM05

|

|

||||||

GALV-295-258-R

GALV-295-258-R

|

|

||||||

178B45

178B45

|

|

||||||

K177A0112

K177A0112

|

|

||||||