STEEL-MAN-DOOR

STEEL-MAN-DOOR

|

|

||||||

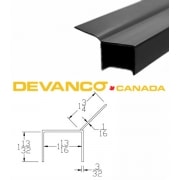

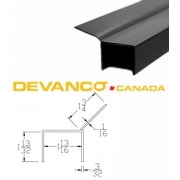

783

783

|

|

||||||

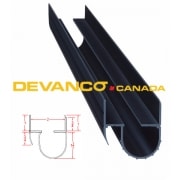

5001-WG-10-MOAK

5001-WG-10-MOAK

|

|

||||||

GL-12-LED

GL-12-LED

|

|

||||||

SF514U

SF514U

|

|

||||||

K72-18615

K72-18615

|

|

||||||

VFD-MOD

VFD-MOD

|

|

||||||

MD-00006

MD-00006

|

|

||||||

PRO-HBH-7521U-R

PRO-HBH-7521U-R

|

|

||||||

6X16SC50

6X16SC50

|

|

||||||

029-98290-PRIMR

029-98290-PRIMR

|

|

||||||

PULLEY007

PULLEY007

|

|

||||||

19-5116

19-5116

|

|

||||||

19-5812-NP

19-5812-NP

|

|

||||||

95358

95358

|

|

||||||

19-5114-NP

19-5114-NP

|

|

||||||

19-48047MN

19-48047MN

|

|

||||||

MGS20-B-2U-05

MGS20-B-2U-05

|

|

||||||

MGS20-B-2U-04

MGS20-B-2U-04

|

|

||||||

DF104.2

DF104.2

|

|

||||||

MARED12

MARED12

|

|

||||||

PRO-GH-10011-U

PRO-GH-10011-U

|

|

||||||

EXA-2000

EXA-2000

|

|

||||||

1003-4"-PER-FT

1003-4"-PER-FT

|

|

||||||

BG790-50-11-HTC

BG790-50-11-HTC

|

|

||||||

1007-1-5/8-12

1007-1-5/8-12

|

|

||||||

1007-1-5/8-10

1007-1-5/8-10

|

|

||||||

TC134-16

TC134-16

|

|

||||||

TC134-10

TC134-10

|

|

||||||

UNI-100-122

UNI-100-122

|

|

||||||

5001-16-CHARCOA

5001-16-CHARCOA

|

|

||||||

1104-ASFT-24FT

1104-ASFT-24FT

|

|

||||||

1104-ASFT-8FT

1104-ASFT-8FT

|

|

||||||

1104-ASFT-9FT

1104-ASFT-9FT

|

|

||||||

50346

50346

|

|

||||||

27-20114

27-20114

|

|

||||||

S142ARNN924

S142ARNN924

|

|

||||||

MB-02102

MB-02102

|

|

||||||

156871

156871

|

|

||||||

27-48-320

27-48-320

|

|

||||||

ME120-BLK-E-4FT

ME120-BLK-E-4FT

|

|

||||||

MP00017

MP00017

|

|

||||||

PRO-LH-5021U-LH

PRO-LH-5021U-LH

|

|

||||||

B014

B014

|

|

||||||

SLT14-18P

SLT14-18P

|

|

||||||

SLT14-22P

SLT14-22P

|

|

||||||

SLT17-22

SLT17-22

|

|

||||||

342.155-CUT

342.155-CUT

|

|

||||||

342.115

342.115

|

|

||||||

GH205-L5

GH205-L5

|

|

||||||

GH151-L5

GH151-L5

|

|

||||||

PL-B12-ARM-CURV

PL-B12-ARM-CURV

|

|

||||||

SL316COP

SL316COP

|

|

||||||

.375-5-1/4-LH-C

.375-5-1/4-LH-C

|

|

||||||

.306-2-RH-C

.306-2-RH-C

|

|

||||||

.273-3-3/4-RH-C

.273-3-3/4-RH-C

|

|

||||||

.225-1-3/4-LH-C

.225-1-3/4-LH-C

|

|

||||||

DF090.2

DF090.2

|

|

||||||

K33-51206-315

K33-51206-315

|

|

||||||

BK301

BK301

|

|

||||||

MGR20-Y-2U-06

MGR20-Y-2U-06

|

|

||||||

MOD074

MOD074

|

|

||||||

OGH-6534-ECB

OGH-6534-ECB

|

|

||||||

201-300-301-01

201-300-301-01

|

|

||||||

OTBH-6433-1-ECB

OTBH-6433-1-ECB

|

|

||||||

OPJ-6234-ECB

OPJ-6234-ECB

|

|

||||||

12-10331

12-10331

|

|

||||||

K1D7545CC

K1D7545CC

|

|

||||||

1044622-REFURB

1044622-REFURB

|

|

||||||

27175B

27175B

|

|

||||||

75W-RS-BULB

75W-RS-BULB

|

|

||||||

375UT

375UT

|

|

||||||

SN1150050

SN1150050

|

|

||||||

802

802

|

|

||||||

MA025

MA025

|

|

||||||

754

754

|

|

||||||

767

767

|

|

||||||

764

764

|

|

||||||

775

775

|

|

||||||

MV00292

MV00292

|

|

||||||

SSZP12-6

SSZP12-6

|

|

||||||

6X42PO50

6X42PO50

|

|

||||||

CH751L5-RH

CH751L5-RH

|

|

||||||

V1001-B

V1001-B

|

|

||||||

703-004

703-004

|

|

||||||

SPR41B60X1

SPR41B60X1

|

|

||||||

CLUTCH-SHAFT-AS

CLUTCH-SHAFT-AS

|

|

||||||

K20-1075B-2LP

K20-1075B-2LP

|

|

||||||

4A1008

4A1008

|

|

||||||

36190T.S

36190T.S

|

|

||||||

BK000-B

BK000-B

|

|

||||||

41A6118

41A6118

|

|

||||||

305-153613

305-153613

|

|

||||||

DS-KIT

DS-KIT

|

|

||||||

71-90503000

71-90503000

|

|

||||||

MWRTA12B

MWRTA12B

|

|

||||||

MDRG

MDRG

|

|

||||||

SHAFT023

SHAFT023

|

|

||||||

MK-00060

MK-00060

|

|

||||||

34299R

34299R

|

|

||||||